Dye production oligopoly, prices may start an upward trend

Release time:

2021-03-03

According to industry media reports, the price of disperse dyes surged on February 27, with all categories increasing by 5000 yuan/ton. The price of disperse black ECT 300% has reached 35000 yuan.

Industry insiders indicate that the current dye Price is relatively low. With the continuous increase in the Price of various chemical raw materials, the increase in orders from dyeing enterprises, and a positive future trend, dye Prices may start to rise. In addition, research by industry leaders Longsheng, RunTu, and JiHua shows that the current inventory level of disperse dyes is the lowest in the past three years.

Furthermore, stricter environmental protection and safety regulations have raised the entry barriers for dye manufacturers, eliminating the cost advantages of small dye manufacturers in environmental protection and safety, and restricting the overall supply of reactive dyes.

Dyes are substances that can dye fibers, fabrics, or other materials with vibrant and fast colors. According to the properties and application methods of dyes, they can be divided into subcategories such as disperse dyes, reactive dyes, sulfur dyes, reduction dyes, acid dyes, and direct dyes.

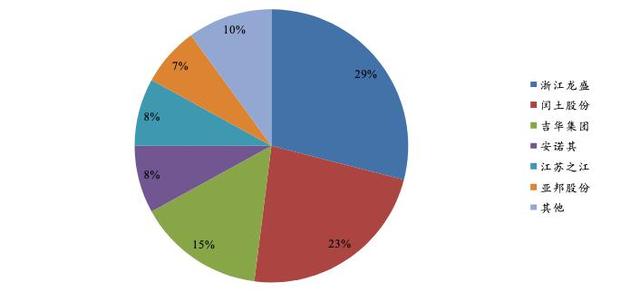

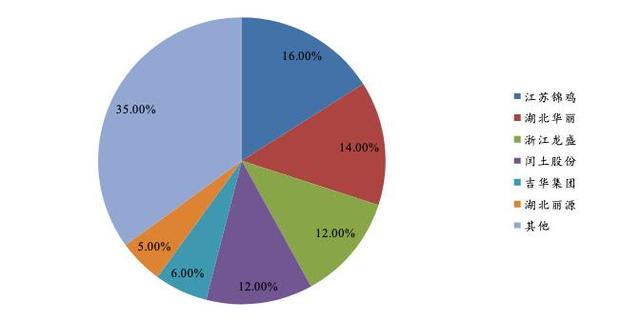

The current dye production pattern generally presents an oligopoly situation, with production capacity concentrated in a few companies. In 2019, China's disperse dye production capacity concentration CR5 was nearly 80%, while reactive dyes were relatively dispersed, with more small and medium-sized enterprises, and CR5 was 66%.

Disperse Dye Production Competitive Landscape:

Data Source: Zhongyuan Securities

Reactive Dye Production Competitive Landscape:

Data Source: Zhongyuan Securities

After the industry's supply-side reform and environmental inspections in 2017/18, the dye industry has formed a high concentration and a profit structure that is heavily weighted towards the upstream. With leading manufacturers controlling pricing power for dyes and dye intermediates, events such as environmental protection, maintenance, and business conditions can lead to high elasticity.

In 2019, the dye center was supported by the upward movement of upstream intermediate costs to a historical high. In 2019, global dye production was 790,000 tons, with disperse dyes, reactive dyes, and other dyes accounting for 338,000 tons, 221,000 tons, and 231,000 tons respectively, representing 43%, 28%, and 29%.

In 2020, the bottoming out of demand in the downstream textile and apparel industry dragged down the Price of dyes and dye intermediates.

Institutions believe that the turning point in the downstream textile and apparel industry + macroeconomic recovery will drive demand growth, and the support of dye intermediates remains, the industry chain will drive a new round of business conditions from the bottom up, and there is significant room for dye Price increases.

Under the impact of the global COVID-19 pandemic, the garment industry in India and Southeast Asian countries has been severely affected, with some orders shifting to China. The phenomenon of textile orders returning to China against the current has become a hot topic in the industry.

At the 2020 China International Textile Machinery Exhibition and ITMA Asia Exhibition, Guangzhou Hongjing Lab Equipment Co., LTD, as a pioneer in intelligent manufacturing dyeing and finishing laboratories in China, showcased its latest intelligent integrated laboratory concept!

The Xida Xing Hongjing dyeing and finishing standard laboratory's overall design adopts a one-stop design for dyeing and finishing laboratories, divided into different functional areas: color measurement and matching area, light box color matching area, cloth cutting area, gray cloth preparation area, fabric opening area, dripping area, manual dripping area, sample dyeing area, reproduction area, and finishing area. Each area is equipped with dyeing and printing experimental equipment independently researched and developed by Hongjing, perfectly matching the laboratory's sample making and reproduction process.

In the first two months of this year, against the backdrop of the low base effect caused by the epidemic in the same period last year, China's total goods trade exports and textile and garment exports both achieved high-speed growth of over 40%. Cumulative exports of textiles and garments reached 301.36 billion yuan, an increase of 44.7%, with textile exports reaching 144.44 billion yuan, an increase of 50.2%, and garment exports reaching 156.92 billion yuan, an increase of 40.0%.