Intelligent manufacturing improves the direct connection rate; dyeing and finishing standard laboratories contribute to industry's take-off

Release time:

2021-05-22

On May 8th, the launch ceremony for Yuanxin Industrial Co., Ltd.'s new Y9000 double-layer stentering machine was successfully held on the fourth floor of the production workshop of Shantou Xida Xing Industrial Co., Ltd. The event was attended by the President of the China Textile Machinery Association,Gu PingPresident of the China Dyeing and Printing Industry Association,Chen ZhihuaGeneral Manager of Yuanxin Industrial,Chen Shaojun、General Manager of Guangzhou Hongjing Lab Equipment Co., LTD and creator of the Hongjing Dyeing and Finishing Standard Laboratory,Huang Zhanhuand dozens of heads of dyeing and printing enterprises.

YuanXin Y9000 double-layer stentering machine new product launch event site

On the day of the event, the guests also visited the Xida Xing Hongjing Dyeing and Finishing Standard Laboratory at the event site.

▲Hongjing Dyeing and Finishing Standard Laboratory▲

This is an intelligent integrated dyeing and finishing standard laboratory established through full cooperation between Xida Xing and Guangzhou Hongjing Lab Equipment Co., LTD, marking a milestone for Xida Xing in transitioning from manual sample making and replication to an intelligent integrated laboratory.

The overall design of the Xida Xing Hongjing Dyeing and Finishing Standard Laboratory adopts a one-stop design for dyeing and finishing testing rooms, divided into different functional areas such as color measurement and matching area, light box color matching area, fabric cutting area, gray fabric preparation, opening area, dripping area, manual dripping area, small sample dyeing area, replication area, and finishing. Each area is equipped with dyeing and printing experimental equipment independently researched and developed by Hongjing, perfectly matching the laboratory's sampling and replication process.

▼Xida Xing Hongjing Dyeing and Finishing Standard Laboratory Functional Zoning▼

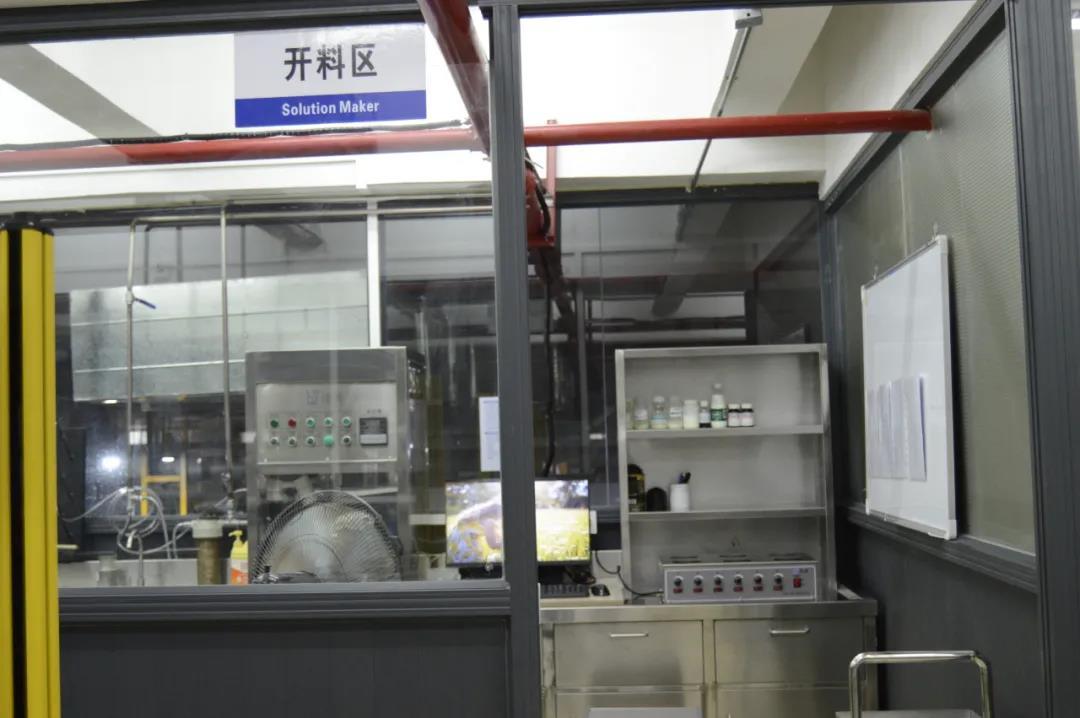

▲Opening Area▲

▲Dropping Area▲

▲Color Measurement and Matching Area▲

▲Color Matching Area▲

▲Replication Area▲

▲Finishing Area▲

▲Fabric Cutting Area, Gray Fabric Preparation▲

▲Manual Suction Area▲

▲Small Sample Dyeing Area▲

Hongjing Dyeing and Finishing Standard Laboratory creatorHuang Zhanhupersonally and patiently explained the advantages and characteristics of the equipment in each area to the visiting guests, and demonstrated the effects of several key pieces of equipment on site—the fully automatic dripping system, the fully automatic boiling and alkali integration machine, and the fully automatic additive machine.

▲Hongjing Dyeing and Finishing Standard Laboratory creatorHuang Zhanhu (Right Image 1)Detailed Explanation▲

Many dyeing and printing company executives marveled at the intelligence of these machines, especially the ingenious design, small footprint, energy efficiency, and other characteristics that piqued the interest and attention of many visiting guests.

Visiting guests marveled at the intelligence of the equipment

With the continuous development of science and technology in China, AI intelligence is gradually entering the dyeing and printing industry. Intelligent integrated laboratories will gradually replace the old dyeing and finishing laboratories that relied on manual experience in the past, becoming a "booster" for the development of the dyeing and printing industry in the new era and providing more efficient returns for more dyeing and printing enterprises. The pace of the times is irresistibly moving forward; only by firmly grasping the opportunities of social development and using the power of science and technology can we remain undefeated in the torrent of history.

Hongjing Dyeing and Finishing Standard Laboratory creatorHuang Zhanhu (Left Image 1)Accepted an interview with "Dyeing Learning and Exchange"

Comprehensively build a digital intelligent laboratory and a dyeing direct-through bridge technology

The great times need a grand vision, and a grand vision needs great responsibility. Recently, Guangdong Polytechnic jointly held a seminar on "Digital Intelligent Laboratory and Dyeing Direct-Through Car Bridge Technology Digital Solution" with Guangzhou Hongjing Lab Equipment Co., LTD, exploring the digital development of the printing and dyeing industry and solutions for dyeing direct-through cars with printing and dyeing graduates. Striving to improve its technological advantages, promote the development of the digital intelligent dyeing and finishing industry, and drive the upgrading of the printing and dyeing industry chain.

On January 10, the 2022 version of OEKO-TEX ® Standard 100 was released, and the new version will come into effect on April 1, 2022.

Textile and apparel export orders have seen a significant drop in July.

Recent data released by the General Administration of Customs shows that clothing and textile exports both declined in July. In RMB terms, textile and clothing exports totaled 181.39 billion yuan, down 18.24% year-on-year and up 1.82% month-on-month, and down 4.21% compared to the same period in 2019; of which, textile exports totaled 75.06 billion yuan, down 33.73% year-on-year and down 6.90% month-on-month, but up 1.30% compared to the same period in 2019; clothing exports totaled 106.33 billion yuan, down 2.08% year-on-year and up 9.03% month-on-month, but down 7.76% compared to the same period in 2019.