Intelligent manufacturing improves the direct connection rate; dyeing and finishing standard laboratories contribute to industry's take-off

Release time:

2021-05-22

On May 8th, the launch ceremony for Yuanxin Industrial Co., Ltd.'s new Y9000 double-layer stentering machine was successfully held on the fourth floor of the production workshop of Shantou Xida Xing Industrial Co., Ltd. The event was attended by the President of the China Textile Machinery Association,Gu PingPresident of the China Dyeing and Printing Industry Association,Chen ZhihuaGeneral Manager of Yuanxin Industrial,Chen Shaojun、General Manager of Guangzhou Hongjing Lab Equipment Co., LTD and creator of the Hongjing Dyeing and Finishing Standard Laboratory,Huang Zhanhuand dozens of heads of dyeing and printing enterprises.

YuanXin Y9000 double-layer stentering machine new product launch event site

On the day of the event, the guests also visited the Xida Xing Hongjing Dyeing and Finishing Standard Laboratory at the event site.

▲Hongjing Dyeing and Finishing Standard Laboratory▲

This is an intelligent integrated dyeing and finishing standard laboratory established through full cooperation between Xida Xing and Guangzhou Hongjing Lab Equipment Co., LTD, marking a milestone for Xida Xing in transitioning from manual sample making and replication to an intelligent integrated laboratory.

The overall design of the Xida Xing Hongjing Dyeing and Finishing Standard Laboratory adopts a one-stop design for dyeing and finishing testing rooms, divided into different functional areas such as color measurement and matching area, light box color matching area, fabric cutting area, gray fabric preparation, opening area, dripping area, manual dripping area, small sample dyeing area, replication area, and finishing. Each area is equipped with dyeing and printing experimental equipment independently researched and developed by Hongjing, perfectly matching the laboratory's sampling and replication process.

▼Xida Xing Hongjing Dyeing and Finishing Standard Laboratory Functional Zoning▼

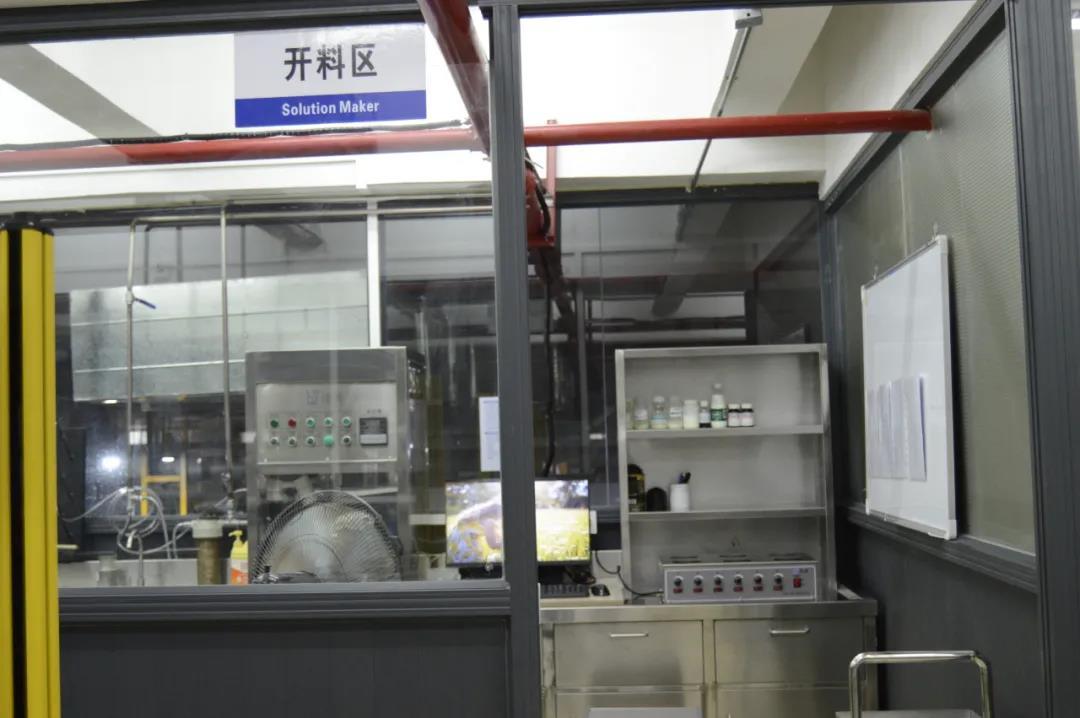

▲Opening Area▲

▲Dropping Area▲

▲Color Measurement and Matching Area▲

▲Color Matching Area▲

▲Replication Area▲

▲Finishing Area▲

▲Fabric Cutting Area, Gray Fabric Preparation▲

▲Manual Suction Area▲

▲Small Sample Dyeing Area▲

Hongjing Dyeing and Finishing Standard Laboratory creatorHuang Zhanhupersonally and patiently explained the advantages and characteristics of the equipment in each area to the visiting guests, and demonstrated the effects of several key pieces of equipment on site—the fully automatic dripping system, the fully automatic boiling and alkali integration machine, and the fully automatic additive machine.

▲Hongjing Dyeing and Finishing Standard Laboratory creatorHuang Zhanhu (Right Image 1)Detailed Explanation▲

Many dyeing and printing company executives marveled at the intelligence of these machines, especially the ingenious design, small footprint, energy efficiency, and other characteristics that piqued the interest and attention of many visiting guests.

Visiting guests marveled at the intelligence of the equipment

With the continuous development of science and technology in China, AI intelligence is gradually entering the dyeing and printing industry. Intelligent integrated laboratories will gradually replace the old dyeing and finishing laboratories that relied on manual experience in the past, becoming a "booster" for the development of the dyeing and printing industry in the new era and providing more efficient returns for more dyeing and printing enterprises. The pace of the times is irresistibly moving forward; only by firmly grasping the opportunities of social development and using the power of science and technology can we remain undefeated in the torrent of history.

Hongjing Dyeing and Finishing Standard Laboratory creatorHuang Zhanhu (Left Image 1)Accepted an interview with "Dyeing Learning and Exchange"

In June 2021, China's textile and apparel exports totaled US$125.153 billion

According to customs statistics, in June 2021, China's exports of textile yarn, fabrics, and made-up articles totaled US$12.5153 billion; from January to June 2021, China's exports of textile yarn, fabrics, and made-up articles totaled US$68.558 billion, a year-on-year decrease of 7.4%; from January to June 2020, China's exports of textile yarn, fabrics, and made-up articles totaled US$74.0173 billion.

Driven by the sustained recovery of domestic and international market demand, the economic operation of China's dyeing industry has further consolidated its recovery trend. From January to May, the output of dyed fabrics has significantly increased compared to the pre-epidemic period, and the industry's operational efficiency has accelerated its recovery. Exports continue to grow, but the trend of "increasing volume but falling prices" has yet to be reversed, and the industry still faces considerable competitive pressure in exports.

The "Belt and Road" initiative unlocks new opportunities for China's industrial textile market

In recent years, with the rapid economic development of countries and regions along the Belt and Road Initiative, such as Southeast Asia and Africa, and the moderate growth in demand from traditional markets such as Europe, America, Japan, and South Korea, overall market demand will be further released, providing Chinese enterprises with further opportunities to expand market space and creating favorable market conditions for the development of China's industrial textile industry.

Riding the wave of national trends, leading domestic textile and apparel brands benefit

Population iteration and Gen Z-led consumption are the main forces driving the rise and evolution of the national trend. From the supply side, leading domestic brands have been steadily improving their internal capabilities in recent years, narrowing the gap with their overseas competitors in brand building, retail operations, supply chain capabilities, and digital system construction, and continuously adapting to and leading the deepening of the national trend.