The Japanese art of tie dyeing

Release time:

2020-11-06

Arimatsu, in central Japan, is the town that tie-dye built. Along its historic main street, fabric merchant houses have stood for centuries. When shopkeepers hang out their shingles here, the signs are a sample of Arimatsu's signature product: a traditional handicraft known as shibori.

Shibori – literally, to squeeze, press or wring – covers a vast array of techniques for manipulating fabric, from stitching, clamping and crumpling, to folding and twisting.

Which is why artisan Hiroshi Murase says "tie-dye" just doesn't begin to convey the splendor of shibori. "Shibori pairs refined skill and painstaking effort with dyeing technique, yielding a sublime mode of textile expression," he said. "Shibori is an art form."

But it was commerce, not art, that set Arimatsu's destiny as shibori mecca.

Shibori had existed in Japan since at least the 8th century. In 1608, the villagers of Arimatsu hit on the idea of hand-dyeing textiles for travelers. Displayed by the bolt, like colorful streamers, shibori souvenirs were a smash hit.

Demand for ever newer, more exquisite shibori fueled a torrent of designs. There are now about 100, often used in combination, with colorful names like Spider Web, Wood Grain and Fawn Spots.

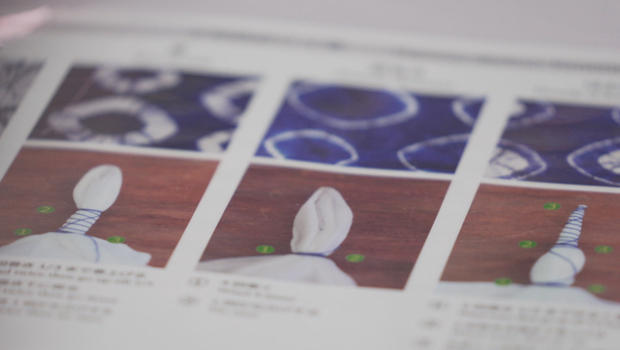

Binding patterns to created tie dye fabrics. CBS NEWS

Correspondent Lucy Craft tried her hand at doing shibori; after some struggling she created her first tie dye. It takes just a few days to get the hang of it. But in order to become a professional-level artisan, it takes years in order to do it much more quickly, efficiently and accurately.

Like Kiyoko Matsuoka and her husband. They are at their bamboo posts every day, pleating and binding fabric. The results will be unique, and not always predictable.

Kiyoko Matsuoka pleats and binds shibori fabric. CBS NEWS

She said, "I've been doing this for 50 years, but there hasn't been a single piece I'm totally satisfied with. I'm always thinking, How could I make it more fabulous?"

Kiyoko Matsuoka's artistry, like much of Arimatsu's shibori creations, will end up at the Hayatsune dyeing factory.

Shibori fabrics are dipped into vats at the Hayatsune dyeing factory. CBS NEWS

Tending the vats of indigo dye is hot, sweaty work. There are few specialty dyers left in Arimatsu.

At last, when dyeing is complete, the binding threads come off – and the fabric takes on three-dimensional form, retaining its crimps and folds.

Beyond cotton and silk, artists are trying shibori on polyester-aluminum, leather, and other non-conventional fabrics.

Shibori is turning up as coral-like lampshades, and on cashmere sweaters.

When it comes to shibori's creative potential, artists say they've only begun to ruffle the surface.

Previous Page

Previous Page:

Under the impact of the global COVID-19 pandemic, the garment industry in India and Southeast Asian countries has been severely affected, with some orders shifting to China. The phenomenon of textile orders returning to China against the current has become a hot topic in the industry.

At the 2020 China International Textile Machinery Exhibition and ITMA Asia Exhibition, Guangzhou Hongjing Lab Equipment Co., LTD, as a pioneer in intelligent manufacturing dyeing and finishing laboratories in China, showcased its latest intelligent integrated laboratory concept!

The Xida Xing Hongjing dyeing and finishing standard laboratory's overall design adopts a one-stop design for dyeing and finishing laboratories, divided into different functional areas: color measurement and matching area, light box color matching area, cloth cutting area, gray cloth preparation area, fabric opening area, dripping area, manual dripping area, sample dyeing area, reproduction area, and finishing area. Each area is equipped with dyeing and printing experimental equipment independently researched and developed by Hongjing, perfectly matching the laboratory's sample making and reproduction process.

In the first two months of this year, against the backdrop of the low base effect caused by the epidemic in the same period last year, China's total goods trade exports and textile and garment exports both achieved high-speed growth of over 40%. Cumulative exports of textiles and garments reached 301.36 billion yuan, an increase of 44.7%, with textile exports reaching 144.44 billion yuan, an increase of 50.2%, and garment exports reaching 156.92 billion yuan, an increase of 40.0%.