The dyeing industry is facing immense pressure due to meager profits. Increasing dyeing costs is imminent.

Release time:

2021-03-03

At the beginning of the new year, the prices of various raw materials and fabrics have risen like a rocket. But strangely, the dyeing fees of dyeing plants, a very important link in the textile industry chain, have not been adjusted. However, this situation should end soon. With the arrival of the Lantern Festival, many dyeing plants have resumed work, and dyeing fees will obviously increase.

In response to this, many textile industry insiders said that raw materials, grey fabrics, and dyeing fees are all rising. Many textile companies have said: Can you be more excessive? Why is it so difficult for us to make money in the textile industry?

Generally speaking, printing and dyeing enterprises will increase their prices two or three times a year. If it is the peak season, there will be more. However, in 2020, due to the overall weakness of the market, printing and dyeing enterprises lost their right to speak. Throughout the year, it seems that only in October, due to market warming and improved orders for dyeing plants, did dyeing fees increase, and the price increase was not very large. Moreover, many dyeing plants with fewer orders did not take this opportunity to increase dyeing fees.

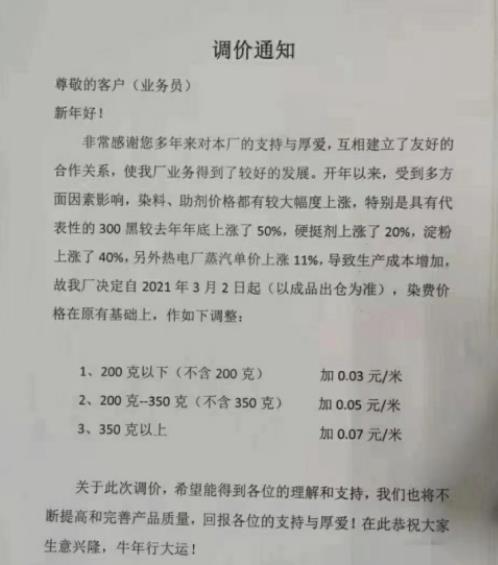

In addition, printing and dyeing enterprises have to face the fact that rents, labor, and environmental protection costs have not been reduced much. Under the condition of meager profits or even losses, the entire printing and dyeing industry is facing enormous pressure. In order to balance production costs, increasing dyeing fees has become imminent.

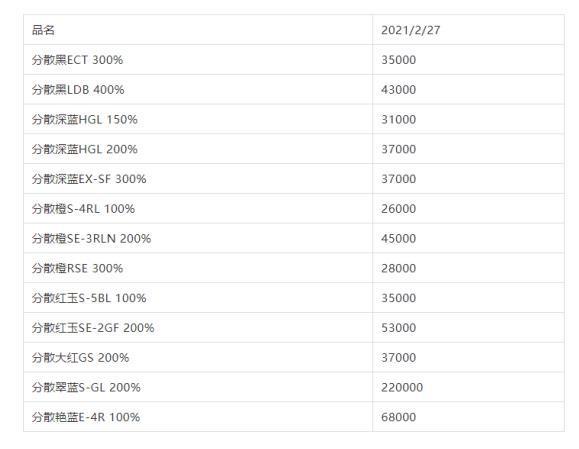

As early as the end of January, affected by factors such as the rise in the Price of basic chemical raw materials, the Price of dye intermediates continued to rise, and the Price of disperse dyes also continued to rise. Among them, disperse black ect increased by 300% to 30 yuan/kg. According to market news, the 300% disperse black ECT has increased from 30 yuan/kg to 35 yuan/kg, and other conventional disperse dyes will increase by 5000 yuan/ton. Disperse black ect increased by 300% in just one month, an increase of more than 16%. The growth rate of other dyes is also similar, which will undoubtedly increase the production cost of dyeing plants and provide a reason for the increase in dyeing fees.

Looking back at 2020, the continuous low Price of dyes kept dyeing plants in a wait-and-see state. At the same time, due to the serious global epidemic last year, the orders of most printing and dyeing enterprises were not as good as in previous years, and the overall demand for dyes was also low. Dyeing plants have become accustomed to not stocking up.

Similar to weaving enterprises, in the face of low-cost raw materials before the year, most enterprises did not have the courage to stock up, resulting in the use of high-cost raw materials for production after the year. In previous years, most dyeing plants increased dyeing fees when the market improved and production was tight. But recently, not only the explosion of orders, but also the soaring cost of dyes has been supported. Both the cost side and the demand side are supporting dyeing plants, and the increase in dyeing fees is inevitable.

However, whether the magnitude and frequency of the increase will increase remains to be answered by the market in March and April.

Under the impact of the global COVID-19 pandemic, the garment industry in India and Southeast Asian countries has been severely affected, with some orders shifting to China. The phenomenon of textile orders returning to China against the current has become a hot topic in the industry.

At the 2020 China International Textile Machinery Exhibition and ITMA Asia Exhibition, Guangzhou Hongjing Lab Equipment Co., LTD, as a pioneer in intelligent manufacturing dyeing and finishing laboratories in China, showcased its latest intelligent integrated laboratory concept!

The Xida Xing Hongjing dyeing and finishing standard laboratory's overall design adopts a one-stop design for dyeing and finishing laboratories, divided into different functional areas: color measurement and matching area, light box color matching area, cloth cutting area, gray cloth preparation area, fabric opening area, dripping area, manual dripping area, sample dyeing area, reproduction area, and finishing area. Each area is equipped with dyeing and printing experimental equipment independently researched and developed by Hongjing, perfectly matching the laboratory's sample making and reproduction process.

In the first two months of this year, against the backdrop of the low base effect caused by the epidemic in the same period last year, China's total goods trade exports and textile and garment exports both achieved high-speed growth of over 40%. Cumulative exports of textiles and garments reached 301.36 billion yuan, an increase of 44.7%, with textile exports reaching 144.44 billion yuan, an increase of 50.2%, and garment exports reaching 156.92 billion yuan, an increase of 40.0%.